The gap discharge is dispersive, and the atmospheric conditions, dust and spherical states may also increase the dispersion. In order to make impulse voltage generator to be reliably adjusted and well synchronized, it is necessary to make the multiple of the overvoltage exceed the scatter range of the ball gap discharge, and some people believe that the overvoltage should be no less than 1.2 times.

At present, high efficiency impulse voltage generator mostly adopts high efficiency loop. Meet the following two conditions:1. If the main capacitor is large, produce lightning surge discharge resistance is too small 2.When the load capacitance is low, operation wave is too large wavefront resistance, which will enable the emergence of natural overvoltage low, only about 1.1 times. Synchronization is not reliable.

To overcome this difficulty, usually in two ways: One is to use the proper arrangement of the circuit increases natural overvoltage; another is to try to make the middle ball gap also trigger ignition, urges each ball gap and discharge.

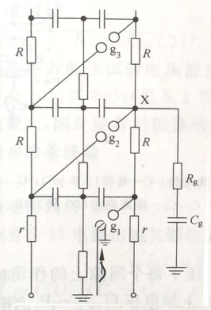

Figure 1: method for increasing stray capacitance and improving synchronous performance

Figure 1 is a double voltage loop of bilateral charging. The natural overvoltage of this circuit is not high. When the G1 is ignited, the overvoltage multiples present on the G2 are at most 1.5 times. If the X point potential changes, the excess voltage will decrease. The Cg in the figure connects several thousand euro Rg and several hundred skins X at the point. As the Rg and Cg have fixed X point potential, the overvoltage multiples on the G2 are 1.5 times. Generally speaking, this kind of impact voltage generator only starts the two stage discharge, and the discharge of the lower level is easier, so it is not necessary to take measures to fix the potential at all levels

Irradiation can induce gap discharge. Generally, the ball gap of the impulse voltage generator is placed on a vertical line. The first stage of the gap discharge produces ultraviolet radiation to the first stage of the gap, causing it to discharge, thereby improving synchronization performance. Figure 2 is the use of each ball gap between the needle and the small spark between the ball to illuminate the ball gap to improve synchronization performance. Figure 2 at charging point, 1,2,3 potential is zero, 1 ', 2', 3 'potential is +U. Each ball is connected to the pin by a small resistance R, which is equal to its own needle potential when charging, and the stray capacitances C2a, C3a and C2b, are free of charge on the C3b.

Figure 2: methods to improve synchronization performance using triggers

The external pulse is sent to the ball skin of the first stage ball gap G1, resulting in a small spark between the two ball's skin and needle pole, thus causing a G1 discharge. The point 1'potential drops to zero, and the point 1 potential changes to -U. The T2b needle potential changed to -U, but the Tzb ball potential remained zero as a result of the transient isolation of R and the transient voltage stabilization of C2b, thus the discharge between the ball skin and the needle electrode.

Similarly, the needle potential of T2a is +U, and the ball skin potential fluctuates as the point 1 'potential drops to zero, and the discharge between the ball skin and the needle is very close. This small spark irradiates the gap and causes G2 discharge. The same goes for G3, g4,... Discharge. In this way, the gap gap discharge can be expanded by triggering the gap discharge, and the synchronization performance is improved.

One way to reduce the dispersion of the spark gap discharge voltage and improves the synchronization performance, so generally use the ball gap symmetry, the gap distance is less than 1/2 diameter, spherical ball to clean, to be arranged in a vertical etc.measures. Exposed gaps are susceptible to external conditions such as air, dust, etc..

For outdoor impact voltage generator, these effects are more significant, which will increase the dispersion of the ball gap discharge. In order to obtain an impact test data, often dozens of times to adjust the voltage, accurately adjust small distance by mechanical transmission, not only troublesome and difficult, so the gas pressure adjustable discharge sphere gap. The ball gap is fixed in the sealed container, and compressed air is used to regulate the air pressure, so that the discharge voltage of the coup can be achieved. This not only eliminates the influence of the external conditions on the discharge, but also adjusts the discharge voltage more accurately

Figure 3 :multistage gap circuit

There is also a multipole gap, as shown in figure 3. With this gap, there is no need to adjust distance or air pressure, but the gap can be conducted within 20 kV to 200 kV, and the dispersity is less than 50 ns. The working principle of this gap is as follows:

The 200 kV voltage is applied between the ends of the AB, and the voltage at each gap is due to the uniform distribution of the R

200 kV/15 = 13.3 kV

In fact, the breakdown voltage at each gap distance is 16.9 kV. At rated voltage, the applied voltage on each gap is only 79% of the breakdown voltage. The P2 ~ P15 is connected by C with the ignition electrode I, and the voltage of I is increased by Ui, and the potential of P2 to P15 is increased by U1.

Such as G1 voltage between U>16.9 kV, gap G1 breakdown. The P2 potential is equal to P1, and G2 follows the breakdown until the G14 breakdown. The P15 potential is equal to P1. The charge applied to the P16 is the charge voltage, and G15, of course, follows the breakdown. Such as "U1" 16.9 kV, may also start simultaneous breakdown at the end, to the central all through.

The U1 voltage is generated by charging 10 kV DC voltage from the outside and charging the C1 via R1, Ri, and N1. 5 kV pulse voltage by C1 to Gi pole needle electrode gap, the Gi breakdown, so Ci to N1 discharge attenuation oscillation wave, coupled to the N3 U1 output voltage to the ignition electrode I, coupled to the N2, send a pulse voltage to the next level of multipole clearance. The discharge spark of G1 is irradiated to G1, G2 and so on, which can greatly reduce the dispersion of discharge.

The multi pole gap is installed on the ignition gap of the impulse generator and the position of the spherical gap in the middle of each pole. The ignition of the first stage is formed by the pulse voltage through the R1C1, and the ignition pulses at the second level are transmitted via the R2C2 path (see Figure 3).

The voltage drop of the multipole gap arc is large, which makes the generator's output voltage and the charge voltage show a nonlinear relationship. The gap is more prone to arc extinction, and the output voltage waveform may jump discontinuously. Some experts think it is not suitable to use it in the impulse voltage generator of transformer factory.