Transformers are divided into voltage transformer and current transformer. The main function is to translate the high voltage into low voltage and high current into low current, so as to realize the measuring instrument, protection devices and automatic control equipment standardization and miniaturization. At the same time it can also be separated from the high voltage system, in order to ensure the safety of personal and equipment.

After many years of experience in the field of the accumulation of debugging experience,we summed up for several types of common transformer fault phenomenon, combined with the fault phenomenon analysis of the causes and treatment methods.

Phenomenon 1: current transformer secondary open-circuit

The current transformer in operation, the secondary load impedance is very small, basically in a short circuit state. After the secondary open load, the primary current does not change, but the secondary current will be zero.Then the primary current will change into the excitation current, which causes the core saturation, and the equipment will cause overheating and transformer burned .

Cause the current transformer secondary open-circuit is generally due to the current lead joint is not strong, terminal damage. Before dealing with this kind of fault, we must first determine whether the circuit is open or open circuit protection. Determine the point of failure, as far as possible to reduce the primary current to disable the primary circuit, the termination of protection. Short circuit test of the secondary terminal with insulated wire or insulation rod. When the data that current transformer measured is right , it can be put into operation. In the operation, we must wear insulation equipment, protect own safety.

Phenomenon 2: Insulation damp

Day and night outdoor work, sun and rain, coupled with the impact of moist air, it is easy to cause the transformer inside the water , resulting in transformer insulation damp. Transformer insulation damp mainly has the following performance: 1. In the process of running with abnormal sound, the lead and the shell has a spark discharge phenomenon 2. main insulation to ground breakdown 3. changed or the second winding inter turn short circuit.

When the insulation is damp, the transformer must be stopped immediately, and the transformer is vacuum dried. When the equipment is safe and dry, the insulation resistance value is measured with the ohmmeter, and when the value is in accordance with the standard range, the transformer can be started to work again.

Phenomenon 3: discharge phenomenon

The discharge phenomena of transformers are divided into corona discharge and partial discharge.

The corona discharge is due to the local electric field around the equipment is too strong. In this case, the equipment should be stopped, the insulating gap between the surface and the core should stuff up of the semiconductor pad or anticorona varnish plugged tightly.

When the transformer is partial discharge, the insulation inside has the pores and other defects. Partial discharge test is needed to measure discharge capacity of transformer. Under normal circumstances, oil immersed transformer partial discharge shall not be larger than 40pC, the voltage of epoxy transformer shall not be larger than 200pC.

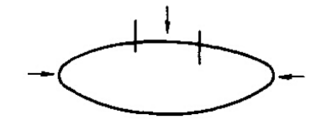

Phenomenon 4: ferromagnetic resonance of voltage transformer

In the case of single phase grounding or closing, the voltage transformer can be saturated, the inductance is reduced, and the inductance and the capacitance of the system are equal. Ferromagnetic resonance will cause the transformer to burn out, which has a serious impact on the normal operation of the transformer substation.

Improve the volt ampere characteristics of transformer ferroresonance can be solved effectively, to adjust the parameters of transducer system in XL and XC, the XC/XL value from the easy to stimulate the ferromagnetic resonance region, and then in the open delta and nonlinear damping resistance in resistance or a coil neutral point of access to the appropriate, which can eliminate the influence of ferromagnetic resonance the voltage transformer.