In order to ensure the safety of electrical equipment, we often use partial discharge tester to test electrical equipment.

|

| HCL 2010 M Partial Discharge Tester |

After the test is finished, the diagram of partial discharge tester will display on the screen based on the measurement results, which is used to show the electrical equipment and the surrounding discharge. How to determine whether it is in a safe range according to the diagram, which requires the analysis of the causes of each diagram.

In this paper, we will list some of the waveform diagram of partial discharge tester, so that the test personnel can correctly judge the results of the test, and record the safety performance of the electrical equipment.

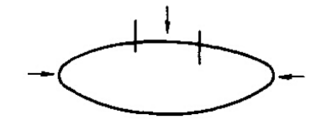

Diagram 1

Typical discharge waveform (1)

This is capacitive discharge waveform, which can occur in insulation or solid insulation bubbles. It occurs in the oil immersed capacitor , insulation or insulation plastic filler in paper. The discharge amplitude and pulse number increase with the voltage .

Diagram 2

Typical discharge waveform (2)

The internal discharge of the interlayer medium may also occur in the carbonized discharge of the insulating board and the climbing of the branches.

Diagram 3

Typical discharge waveform (3)

The discharge of an insulating medium that is in contact with each other and the discharge in the oil impregnated paper capacitor.

Diagram 4

Typical discharge waveform (4)

In the same medium, different sizes of bubbles may also form this kind of circular, mainly in the epoxy casting insulation. Discharge volume changes with the voltage, such as the gap between the capacitor layer.

Diagram 5

In the insulation of an electric motor, the discharge in the mica insulation of the motor, and the amount of discharge varies with the time and pressure of the copy.

Diagram 6

The discharge occurs between the metal and the dielectric surface ,which may be an air gap between the metal and the medium, or the surface conductivity is uneven.

Diagram 7

The surface of the metal electrode is discharged, and the exposed metal surface and the medium are discharged. The air bubbles between the metal and the medium or the air bubbles in the lift may contain impurities such as metal or carbon.

Diagram 8

A small part of a metal foil or metallized sheet in a capacitor can move under an electric field.

Diagram 9

Discharge of poor contact or suspended metal , and the test circuit is not reliable connection. The pulse amplitude of the discharge pulse is equal to the positive and negative half cycle of the discharge. The oscilloscope can observe the discharge pulse pairs, figure (a),(b) this is because the oscilloscope effect caused by visual error caused by light.

Diagram 10

Contact noise discharge, poor contact between metal or semiconductor shielding layer. At the same time, the discharge distribution of the noise is small on the two sides of the test voltage. As the voltage increases, the noise discharge coverage increases, as shown in figure (a). Motor carbon brush to form a spark discharge may occur in this waveform,figure (b).

Diagram 11

The metal electrode discharge concentration field, the amplitude distribution in the isometric peak voltage on both sides, with the corona and air discharge in the same voltage, the discharge AC voltage exists in both positive and negative half weeks, but 2.5 weeks amplitude asymmetry, discharge pulse amplitude larger in the positive half cycle, then discharge at high potential, and vice versa in low potential. Similar in oil and gas.

Diagram 12

Suspended discharge in oil insulation and creepage, pulse number, the critical voltage, discharge is not stable. Sometimes for a few seconds, or stop a few seconds without discharge. The discharge is with large amplitude, but like the external random disturbance which need combined with waveform and judge the disturbance caused by the discharge of fluorescent lamp.

Diagram 13

Discharge by fluorescent lamp.

Diagram 14

The interference of silicon controlled rectifier is symmetrically distributed, and sometimes it is a single pulse

Diagram 15

In the case of asynchronous induction motor, the response of the motor is independent of the test voltage, which may be caused by the large asynchronous motor, and may be caused by the large load of the transformer. However, when the generator is turned on for the test, the difference between the generator frequency and the power supply of the system instrument will cause the discharge display waveform to rotate.

Diagram 16

Industrial high frequency equipment interference, industrial high frequency equipment such as ultrasonic generator, induction heater etc.

Diagram 17

The interference of amplitude modulated sine wave signal is mainly caused by the high power high frequency power amplification or the radio emission or radiation interference of the oscillator and the interference of the radio station.

Diagram 18

corona discharge

Corona discharge occurs at the metal tip or the edge of the electric field. The corona discharge occurs only in the half of the test voltage, and symmetrically distributed on both sides of the voltage peak, figure (a). As the voltage increases, the number of pulses (width) increases symmetrically, as shown in figure (b). If the discharge tip electrode is in a high potential, the corona discharge occurs at the negative half of the test voltage. If the tip electrode is in the ground potential, the discharge pulse appears in the positive half cycle. On one electrode, the initial corona appeared in 1.5 weeks, but when the voltage rises above the initial voltage of many, in the other 1.5 weeks will also appear in large amplitude, discharge less pulses, as shown in figure (c).

No comments:

Post a Comment